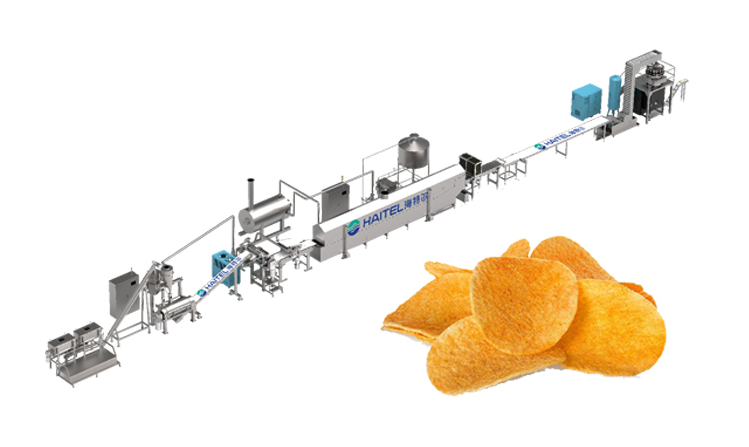

Automatic potato chips production line

Description:

The potato chips production line is a fully automatic composite potato chips production line newly developed by Jiangsu haitel Machinery Co., Ltd, including the whole process automation process of raw material mixing and stirring, pressing dough, printing and molding, frying molding, seasoning, cooling and transportation, and completing the whole production process from powdered raw materials to finished potato chips; At the same time, with the fully automatic crushing and recycling mechanism and frying filtration mechanism newly developed by haitel, the functions of waste material recycling and oil residue filtration can be effectively realized.

The food contact part and most other parts of this production line are made of stainless steel, with stable operation and high degree of automation. Products can be packaged in vertical bags, pillow boxes or paper drums. They are in great demand, crisp and delicious, suitable for all ages.

Main performance and features:

- PLC control, intuitive display and simple operation.

- Most of the equipment is made of food grade 304 stainless steel

- With the new recycling structure, the leftover materials are recycled and reused, and the use efficiency of raw materials is high

- The integrated molding die can obtain potato chips with uniform shape, which is convenient for sorting and barrel packing

- New filtering structure and effective oil residue

- It can be equipped with vertical bag packaging, bag feeder packaging or paper bucket packaging

Device parameters

1. Equipment size: 35m(L)×8m(W)×5mm(H) (excluding packaging part);

2. Working power supply: equipment 380VAC±5﹪, 50HZ, rated power approximately45KW;

3. Compressed air: 0.5~0.7 MPa; air compressor is optional.

4. Capacity: 150Kg/h;

5. Staffing: 5-6 people are required for the production line (excluding packaging part), deep-fried (including

(Frying) is equipped with 3 people before the process, responsible for raw material preparation,

In addition, production monitoring and assistance; after frying, there are 2-3 people who are responsible for the arrangement and assistance of potato chips; the number of personnel for trial production and packaging should be adjusted according to the actual situation.

6. Water: a small amount of water is used for raw material mixing and cooling of the tablet roll

Pre-sale

1.Confirm machine type: Negotiate with clients to seclect the correct machine according to customers’ requirment.

2.Quote and Sign firm contract: After confirm with customers with all details, such as payment terms, model, delivery time, send official quotation to clients.

After-sale

1.When equipments arrive in clients factory,send engineers there for installation and ensure customers know how to operate the machine.

2.In order to improve our products,we keep in close contact with customers to know their feedbacks and suggestions.

3.From the date of the buyer receive the machines, free warrant for 12 months.

Packaging and Delivery

1. Prompt deliver at the very day.

2. Sophisticated and professional logistic agent.

3. Well-trained and disciplined packing team.

4. After-sale service:. Any questions or problems after receiving the product, please feel free to contact us. Problems would be solved for you immediately.

Quality Guarantee

The quality of the production line will have 12 month warranty since the installtion in the buyer's factory.

• Top Food machine manufacturer in China

• 20000 square meters production plants

• Over 22 years of experience

• Made-in-China’s Gold member since 2009

• CE, ISO9001 certified

• Engineers able to offer overseas installation and testing, and training.The plant layout design, assembling, installation and debugging, start-up and local team training will be FREE at no cost.

• Prompt delivery and flexible payment terms

• Small order is welcomed

• professinal team with strong technical and R&D knowledge to develop advanced food equipments

• save labor cost and improve the capacity.