Hard Candy Making Machine:What do you need to know?

|

Chapter I. What is hard candy?

Hard candy is a candy made by boiling at high temperature. The dry solid content is very high, about more than 97%. Sugar is hard and brittle, so it is called hard sugar. It belongs to amorphous amorphous structure. The specific gravity is between 1.4 and 1.5, and the content of reducing sugar ranges from 10 to 18%. It melts slowly at the entrance and is chewable. Sugar bodies are transparent, translucent and opaque, as well as drawn into mercerized shape.

The quality characteristics of hard candy are bright and transparent color, firm and brittle texture, neat and symmetrical particles, and the basic component is sucrose. It has fruit flavor and pure sweetness, without bitterness and scorch, easy to preserve and low cost。

Chapter 2. What kid of hard candy do you need to make?

Hard candy varieties include orange, banana, lemon, pineapple, almond, cream, coconut, cocoa, coffee, tea and other flavors of hard candy. From the appearance, it can be divided into baked flowers, white, mixed sand and mercerized. Hard candy can be made into round, oval, rectangular, flower, animal, spherical and other shapes。

At present, there are also some functional hard candy on the market, such as various vitamin hard candy, such as cough hard candy and vitamin C hard candy

Chapter 3. How much does it cost to invest in a hard sugar production line?

Invest in a complete set of hard candy production line, which needs sugar melting machine, sugar boiling machine, sugar kneading machine, roller bed machine, stretching machine, cooling equipment, hard candy forming machine, cooling equipment, conveying equipment and hard candy packaging machine.

Chapter 4. Why choose haitel hard candy production line?

Founded in 1997, haitel is a professional intelligent full case service provider of food and drug processing and packaging machine production line. It supports customization and can produce a complete set of hard sugar production line from raw material processing to finished product packaging, bagging and packing, saving you time and labor cost. It can ensure that after receiving the goods, your whole set of hard candy production line can use the whole set of equipment perfectly, and put it into production at the first time. You don't need to spend more time and cost to debug the connection between different equipment and solve the problems in use.

Chapter 5. How many kinds of hard candy production lines can haitel make?

NO1:HTL-B1/B2 Center Filling Milk (Hard) Candy Production Line

The sandwich milk candy (hard candy) production line is a multi-functional candy production line independently developed and produced by haitel. It is composed of sugar melting pot, sugar boiling machine, sugar kneading machine, cooling table, roller bed machine, stretching machine, conveyor, B1/B2 hard candy molding machine, cooling screen and candy packaging machine. The candy molding effect is good, there are no bubbles and the production capacity is high.

HTL-B1/B2 Center Filling Milk (Hard) Candy Production Line,It can produce hard candy, milk candy, sandwich hard candy, toffee and crispy candy。

HTL-B1/B2 Video display:

NO2:HTL-T660 Center Filling Candy (Hard) Production line

The sandwich hard candy production line is a high-yield hard candy and sandwich sugar production line independently developed and produced by haitel. The candy has good molding effect and no bubbles. It is composed of sugar melting pot, sugar boiling machine, sugar kneading machine, cooling table, roller bed machine, stretching machine, conveyor, T660 hard candy forming machine, cooling cabinet and candy packaging machine. If it is made of Certer filling hard candy, it can be equipped with pulp conveyor.

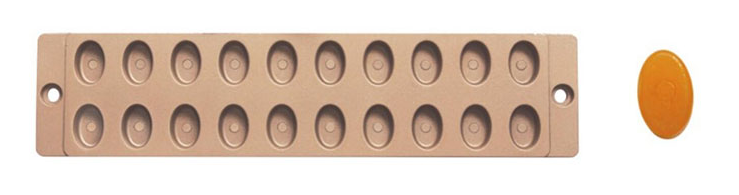

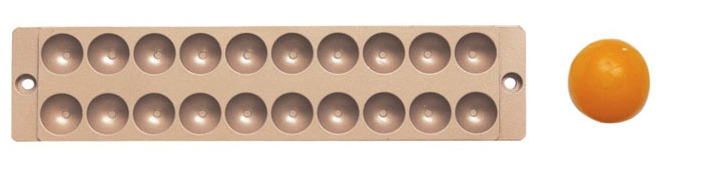

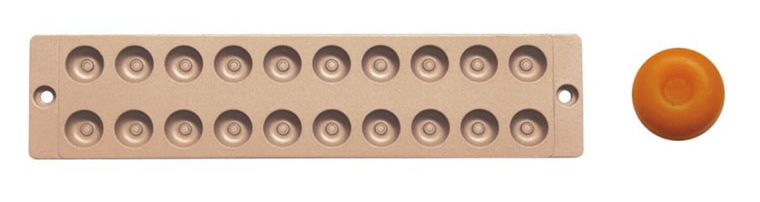

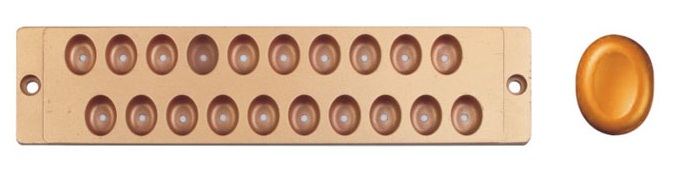

HTL-T660 Hard candy machine It can make round, oval, spherical and other hard candy and sandwich hard candy with different shapes.

HTL-T660 Video display:

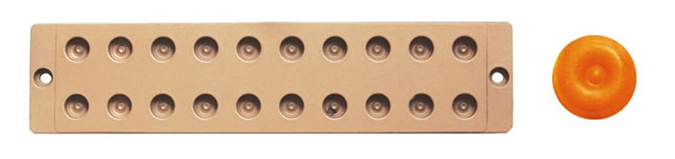

NO3:HTL-T150/T300/T450/T600 Fully automatic hard candy depositing machine

The production line is a full-automatic hard candy pouring production line independently developed and produced by haitel, which can meet the needs of multiple shapes and colors. The machine adopts continuous pouring, automatic demoulding, fan forced cooling and other devices as an integrated automatic hard candy pouring machine. It can also produce high-quality hard candy and lollipops with multiple shapes and colors by changing molds or pouring heads. Good stability, ensure the quality and output of candy in the long-term production process, and save manpower, so as to reduce the production cost.

HTL-T150/T300/T450/T600 Fully automatic hard candy depositing machine It can pour and produce hard candy of various shapes and colors, such as round hard candy, square hard candy, rectangular hard candy, oval hard candy, animal hard candy, etc,It can be customized according to requirements。

HTL-T150 Video display:

Chapter 6. What kind of after-sales service can hytel provide you?

The products shall be provided with one-year warranty service and lifelong maintenance service. During the warranty period, if there are quality problems, they will be repaired, replaced, installed and debugged free of charge according to the principle of "Three Guarantees", and provide product installation and debugging services and training services; After the free warranty period of the product, our company will continue to provide long-term preferential technical services for the product, including technical support, product upgrading, rapid response to faults and technical consultation of relevant personnel; Provide 24-hour, all-day real-time service. Users can submit service declarations to the customer service center in different ways. We ensure that users' problems can be responded to in time at any time