Choose Gummy Bear Making Machine:Information You Need to know!

|

Chapter 1: What is Jelly gummy candy ?

Jelly gummy candy is a kind of candy with high moisture content and soft texture, which is made of granulated sugar and starch syrup as the main raw materials, agar, modified starch, gelatin and pectin as the coagulant, through boiling, molding and other processes.

The main characteristics of gel candy are transparent and glossy in appearance, soft, sticky and elastic in taste; The physical state system is a relatively stable colloidal dispersion system; High water content. The representative varieties of gel candy include denatured starch gummy candy, gelatin gummy candy, carrageenan gummy candy, agar gummy candy, pectin gummy candy, gum gummy candy, etc.

Chapter 2: What is the technological process of Jelly gummy candy making?

Gelatinization → sugar boiling → blending - pouring molding → cooling → demoulding → packaging

Chapter 3: What is the investment prospect of Jelly gummy candy now?

Pectin soft candy is a popular small food in the food industry market at home and abroad. From 2021 to now, vitamin pectin soft candy is popular in the candy industry and health food industry. In the future, vitamin candy will slowly replace vitamin candy in the candy market. The market is traditional candy, because candy with various vitamins is relatively healthy and suitable for the current market

Chapter 4: How to choose commercial Jelly gummy candy machinery

Jelly gummy candy making machine It is a set of automatic jelly gummy candy pouring production line controlled by PLC, which is composed of sugar boiling pot, glue melting pot, mixing pot, pouring molding machine, freezer, demoulding, sand roller and packaging machine.

Chapter 5: Can Jelly gummy candy machinery produce only one shape of Jelly gummy candy?

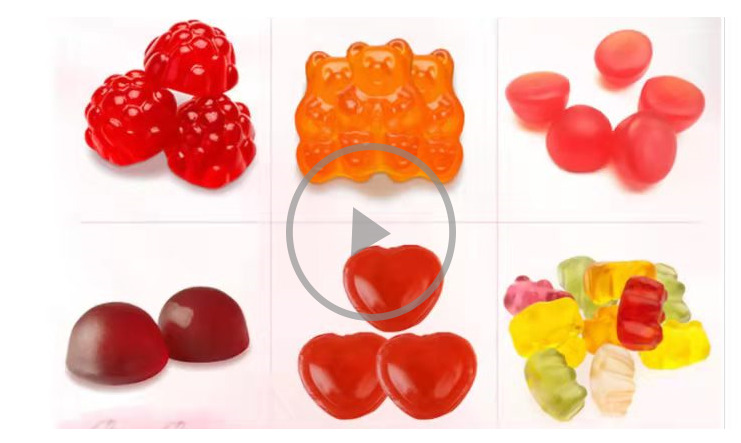

The automatic Jelly gummy candy pouring production line can produce pectin candy with different shapes, two or three colors,gelatin gummy candy, carrageenan gummy candy, agar gummy candy, pectin gummy candy, gum gummy candy.

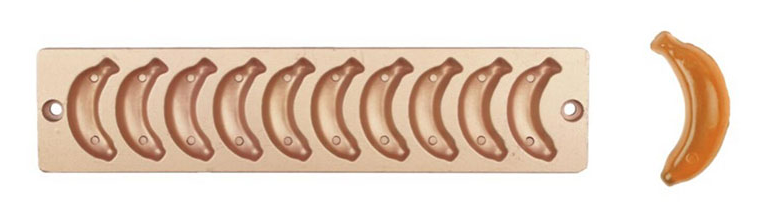

Gummy candy The shape can be customized according to requirements:

Chapter 7: Why trust haitel Jelly gummy candy machinery

Haitel is a professional intelligent case service provider of food and drug processing and packaging production line. It provides intelligent system solutions for processing and packaging production lines for customers in the global food and drug manufacturing industry!

Jelly gummy candy machine describe:

Haitel automatic Jelly gummy candy pouring production line can meet the needs of various shapes and colors. The machine adopts continuous pouring, automatic demoulding, fan forced cooling and other devices as an integrated automatic soft candy pouring machine. It is an ideal equipment for continuous production of high-grade soft candy and functional soft candy. It can produce high-quality single and double color soft candy, gel soft candy, carrageenan soft candy, pectin soft candy, etc; The gel soft candy with high quality, various shapes and colors can also be produced by changing the mold or pouring head. It can realize the quantitative filling and mixing of essence pigment acid; Good stability, ensure the quality and output of candy in the long-term production process, and save manpower, so as to reduce the production cost.

Jelly gummy candy machine characteristic:

1、PLC /computer process control available;

2、An LED touch panel for easy operating;

3、The production capacity is 150kg/h,300kg/h,450kg/h,600kg/h or more;

4、The contacting food parts are made of hygienic Stainless Steel SUS304;

5、Optional (mass) flowing controlled by Frequency inverters;

6、In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid;

7、Dosing pumps for the automatic injection of colors, flavors and acids;

8、One set of extra jam paste injection system for making fruit jam-center filled candies(optional);

9、Use automatic steam control system instead of the manual steam valve which control a stable steam pressure supplying to the cooking;

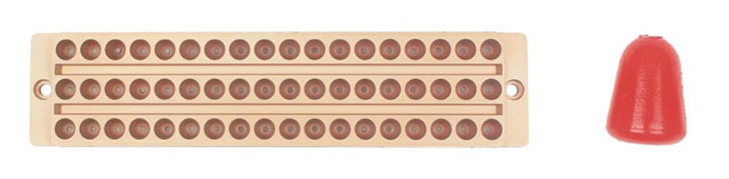

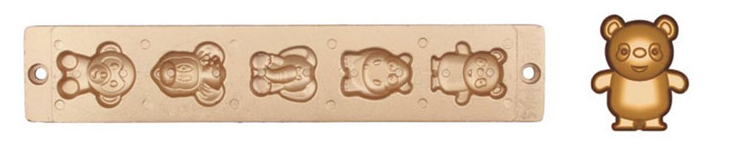

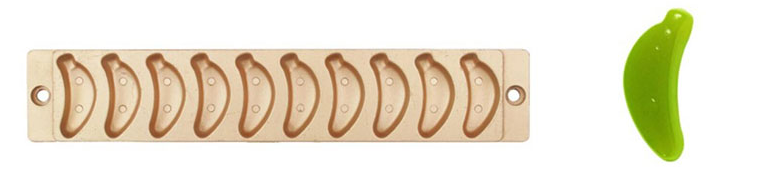

10、Moulds can be made according to the candies samples provided by the customer.

Gummy candy machine Video display:

Product certification and certificate:

Chapter 8: How can haitel provide you with after-sales guarantee。

The products shall be provided with one-year warranty service and lifelong maintenance service. During the warranty period, if there are quality problems, they will be repaired, replaced, installed and debugged free of charge according to the principle of "Three Guarantees", and provide product installation and debugging services and training services; After the free warranty period of the product, our company will continue to provide long-term preferential technical services for the product, including technical support, product upgrading, rapid response to faults and technical consultation of relevant personnel; Provide 24-hour, all-day real-time service. Users can submit service declarations to the customer service center in different ways. We ensure that users' problems can be responded to in time at any time